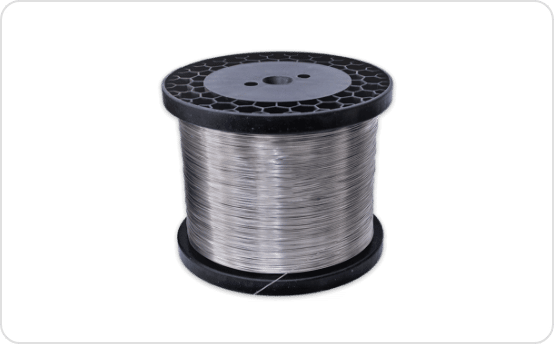

Top-grade Tin Plated Copper Wire

With years of experience, we can manufacture and provide top-grade Tin plated copper wire as per our customers’ specific industrial requirements. Our Tin plated copper wire is made from the highest quality raw materials.

Tin Plated Copper Wire is composed of a copper core covered by a concentric tin plating with the help of electroplating process. The operating temperature of Tin plated copper can work up to 150°C.

- Tin Plated Copper Wire Properties

- High-Quality Tin Plated Copper Wire Manufacturer

Triskele Wires and Cables offers the highest quality Tin plated copper wire to a variety of industries with specific customized requirements. We are the best tin plated copper wire manufacturer in the market because we strive to exceed our customers’ expectations.

- Tin Plated Copper Wire Sizes and Customizations

Being a custom wire manufacturing company, we are able to meet a wide range of customer-specific requirements – from low quantity specialty orders to high volume orders. We always make sure that your industry-specific custom requirements are fulfilled with quality and excellence which boosts confidence in our customers and their products.

- Product Specifications

| Solid Tin Plated Copper Wire Size Range (Diameter) | AWG 12 to AWG 40 (2.00 mm to 0.079 7mm) / SWG 14 to SWG 44 |

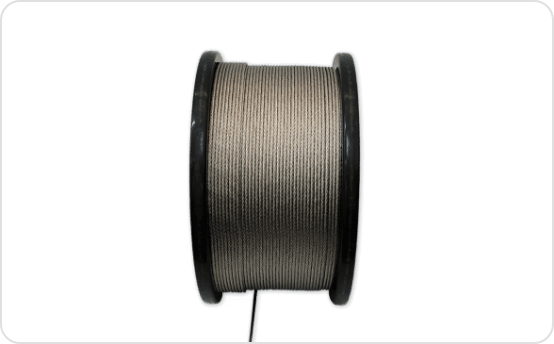

| Stranded Tin Plated Copper Wire Size Range (Diameter) | AWG 32 to AWG 2 |

| AWG 32 to AWG 2 | B 33 |

| Configurations of Stranded/Bunch/Rope Construction | True Concentric |

| Equilay Concentric | |

| Equilay Concentric | |

| Unilay | |

| Bunched Stranding | |

| Rope Lay Stranding |

- Advantages of Tin Plated Copper Wire

- Insulated wires made from Tin plated copper wire were developed for applications where operating environments may weather conventional conductors.

- The operating temperature can be raised up to 150°C for insulated wires made from Tin plated copper wire.

- Tin plated copper wire offers enhanced solderability compared to bare copper conductors.

- Tin plating is cost effective relatively if compared with other alloys and metals.

- Limitations of Tin Plated Copper Wire

- Tin plated copper wires withstand low operating temperatures.

- Tin oxidation through copper migration over time leads to degraded solderability even at room temperature.

- Insulation is required otherwise Tin plated copper wires turn blackish and are not recommended for long life span in an open environment.

- Limited shelf life for solderability.

- Tin and copper interact with each other to form an intermetallic alloy over a period of time, and the rate of formation is determined by the temperature but occurs even at room temperature. This is inevitable even with insulation.

- Applications