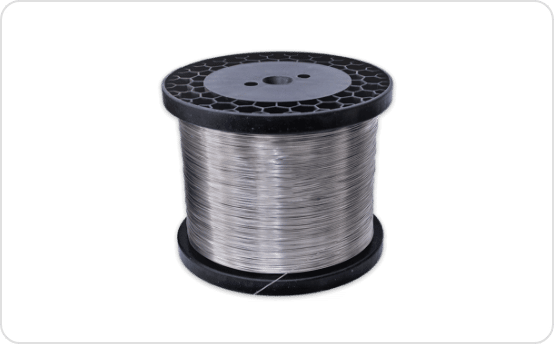

High-Quality Silver Plated Copper Wire

Being an industry leader of high-quality silver plated copper wire manufacturing, we strive to exceed our customers’ expectations by providing highest quality silver plated copper wire. We only use the best quality raw materials and manufacturing processes.

With years of experience in manufacturing silver plated copper wire, we are equipped to meet our customers’ specific industrial requirements. Triskele Wires and Cables manufactured silver plated copper wire is suitable for a wide variety of industries.

Silver Plated Copper Wire is composed of a copper conductor covered with concentric silver plating to provide a highly conductive, corrosion & abrasion-resistant, and excellent solderable surface. In addition, when silver and copper are used together in the application, the electrical charge and conductivity are effectively managed to accommodate fluctuating currents.

- Features of Silver Plated Copper Wire

Silver is the only metal with a higher electrical conductivity than copper and thus, silver enhances the conductivity of copper when plated onto it. Silver also offers the highest optical reflectivity and improved thermal conductivity.

Silver-plated copper wires possess excellent high-temperature lubricity; therefore, it is a preferred coating for high friction applications on surfaces exposed to high temperatures up to 1200F. Therefore, silver plated copper wires are widely used in cable and electronic applications where signal stability is a concern.

- Best Silver-Plated Copper Wire Manufacturer

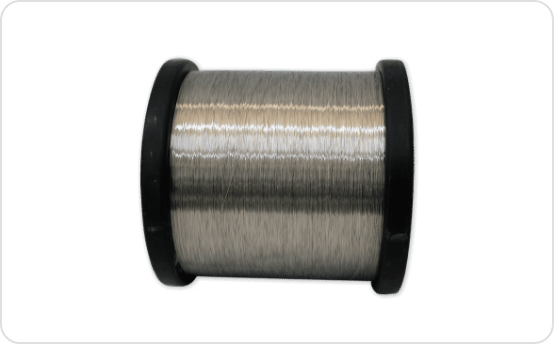

Triskele Wires and Cables’s silver-plated copper wire provides the most concentric coating thickness available to ensure complete coverage of the wire substrate. Ultrafine wires require a higher percentage of silver plating while heavier wires can use a more economical lower percentage.

Being a custom wire manufacturing company, we can meet a wide range of our customer’s specific requirements – from low quantity specialty orders to high volume orders. Our manufacturing processes are managed by the certified quality management system.

- Customer Specific Customizations Available

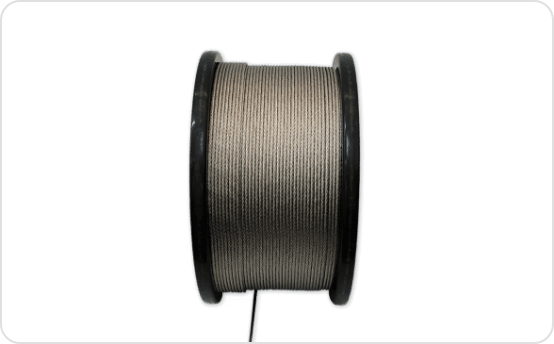

With our 3+ decades of experience, we can offer specific and customised solutions to our customers. We supply to some of the leading wire and cable manufacturers who then supply end products to the Aerospace, Medical, Electronics and Telecommunications industries demanding superior quality.

- Product Specifications

| Solid Silver Plated Copper Wire Size Range (Diameter) | AWG 12 to AWG 40 (2.00 mm to 0.079 mm)/ SWG 14 to SWG 44 |

| Stranded Silver Plated Copper Wire Size Range (Diameter) | AWG 32 to AWG |

| Silver Plating Range as per ASTM B 298 | 1 to 20 microns |

| Solid Silver Plated Copper Wire Specifications | ASTM B 298 |

| Stranded Silver Plated Copper Wire Specifications | ASTM B 286 |

| Configurations of Stranded/Bunch/Rope Construction | True Concentric |

| Equilay Concentric | |

| Unidirectional Concentric | |

| Unilay | |

| Bunched Stranding | |

| Rope Lay Stranding |

- Advantages of Silver Plating

- Silver has excellent conductivity and offers performance at higher transmission frequencies (skin effect).

- Withstands high temperatures and is not affected at sub-zero temperatures.

- Provides high corrosion resistivity.

- Gives low contact resistance in the high-frequency circuit.

- Excellent solderability and weldability characteristics.

- Excellent signal transmission rate.

- Provides aesthetically bright and shiny surfaces.

- Limitations of Silver Plating

- The high cost and low tensile strength limit its use for special applications.

- Rated temperature up to 200°C.

- Requires controlled parameters of insulation processing otherwise, it will be weathered.

- Applications

PTFE, FEP, TEFZEL, POLYAMIDE and other insulated high-temperature wires and cables, high-frequency cables, speaker cables, radio frequency coaxial cables, cables for data transmission, shielding (ESD/EMV), Twinax cables, oxygen sensor cables, colored wires of high-quality standards, textile wire, high-frequency applications, Micro cables, electrical screens, jumpers in PCB etc.

Standard Specification for Stranded Silver Plated Copper Wire

| CONDUCTOR | MINIMUM ELONGATION (%) | MAXIMUM | WEIGHT | LENGTH | |||||

|---|---|---|---|---|---|---|---|---|---|

| SIZE | NOM DIA | NOM DIA | RESISTANCE AT 20°C | NOMINAL | NOMINAL | NOMINAL | NOMINAL | ||

| AWG | MM | INCH | Ω/KM | Ω/MFT | KG/KM | LBS/MFT | M/KG | FT/LB | |

| 12 | 2.0523 | 0.0808 | 25 | 5.320 | 1.622 | 29.406 | 19.7600 | 34.01 | 50.61 |

| 13 | 1.8288 | 0.0720 | 25 | 6.700 | 2.042 | 23.349 | 15.6900 | 42.83 | 63.73 |

| 14 | 1.6281 | 0.0641 | 25 | 8.454 | 2.577 | 18.513 | 12.4400 | 54.02 | 80.39 |

| 15 | 1.4503 | 0.0571 | 25 | 10.654 | 3.247 | 14.687 | 9.8690 | 68.09 | 101.33 |

| 16 | 1.2903 | 0.0508 | 25 | 13.460 | 4.103 | 11.624 | 7.8110 | 86.03 | 128.02 |

| 17 | 1.1506 | 0.0453 | 25 | 16.927 | 5.159 | 9.244 | 6.2120 | 108.17 | 160.98 |

| 18 | 1.0236 | 0.0403 | 25 | 21.388 | 6.519 | 7.316 | 4.9160 | 136.69 | 203.42 |

| 19 | 0.9119 | 0.0359 | 25 | 26.948 | 8.214 | 5.805 | 3.9010 | 172.26 | 256.34 |

| 20 | 0.8128 | 0.0320 | 25 | 33.920 | 10.339 | 4.613 | 3.1000 | 216.76 | 322.58 |

| 21 | 0.7239 | 0.0285 | 25 | 42.763 | 13.034 | 3.659 | 2.4590 | 273.27 | 406.67 |

| 22 | 0.6426 | 0.0253 | 25 | 54.268 | 16.541 | 2.884 | 1.9380 | 346.73 | 516.00 |

| 23 | 0.5740 | 0.0226 | 25 | 68.014 | 20.731 | 2.301 | 1.5460 | 434.65 | 646.83 |

| 24 | 0.5105 | 0.0201 | 20 | 85.987 | 26.209 | 1.820 | 1.2230 | 549.44 | 817.66 |

| 25 | 0.4547 | 0.0179 | 20 | 108.386 | 33.036 | 1.443 | 0.9699 | 692.82 | 1031.03 |

| 26 | 0.4039 | 0.0159 | 20 | 137.365 | 41.869 | 1.139 | 0.7652 | 878.16 | 1306.85 |

| 27 | 0.3607 | 0.0142 | 20 | 172.238 | 52.498 | 0.908 | 0.6104 | 1100.87 | 1638.27 |

| 28 | 0.3200 | 0.0126 | 20 | 218.838 | 66.702 | 0.715 | 0.4806 | 1398.19 | 2080.73 |

| 29 | 0.2870 | 0.0113 | 20 | 272.056 | 82.923 | 0.575 | 0.3865 | 1738.60 | 2587.32 |

| 30 | 0.2540 | 0.0100 | 20 | 347.340 | 105.869 | 0.450 | 0.3027 | 2219.92 | 3303.60 |

| 31 | 0.2261 | 0.0089 | 20 | 438.350 | 133.609 | 0.357 | 0.2398 | 2802.21 | 4170.14 |

| 32 | 0.2032 | 0.0080 | 15 | 542.719 | 165.421 | 0.288 | 0.1937 | 3469.12 | 5162.62 |

| 33 | 0.1803 | 0.0071 | 15 | 689.336 | 210.110 | 0.227 | 0.1526 | 4403.47 | 6553.08 |

| 34 | 0.1600 | 0.0063 | 15 | 875.351 | 266.807 | 0.179 | 0.1201 | 5595.08 | 8326.39 |

| 35 | 0.1422 | 0.0056 | 15 | 1108.213 | 337.783 | 0.141 | 0.0949 | 7080.81 | 10537.41 |

| 36 | 0.1270 | 0.0050 | 15 | 1389.361 | 423.477 | 0.113 | 0.0757 | 8876.74 | 13210.04 |

| 37 | 0.1143 | 0.0045 | 15 | 1715.260 | 522.811 | 0.091 | 0.0613 | 10961.97 | 16313.21 |

| 38 | 0.1016 | 0.0040 | 15 | 2170.876 | 661.683 | 0.072 | 0.0484 | 13883.66 | 20661.16 |

| 39 | 0.0889 | 0.0035 | 15 | 2835.430 | 864.239 | 0.055 | 0.0371 | 18112.37 | 26954.18 |

| 40 | 0.0787 | 0.0031 | 15 | 3618.036 | 1102.780 | 0.043 | 0.0291 | 23091.72 | 34364.26 |

| CONDUCTOR | LAY LENGTH | DIAMETER IN MM | DIAMETER IN INCH | MAXIMUM RESISTANCE AT 20°C | WEIGHT | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SIZE AWG | STRAND | NOMINAL MM | NOMINAL INCH | MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | Ω/KM | Ω/MFT | NOMINAL KG/KM | MAXIMUM KG/KM | NOMINAL LBS/MFT | MAXIMUM LBS/MFT |

| 4/0 | 37×57/30 | 190.5000 | 7.5000 | 14.7320 | 15.3416 | 0.5800 | 0.6040 | 0.204 | 0.062 | 997.070 | 1017.900 | 670.000 | 684.000 |

| 3/0 | 37×45/30 | 165.1000 | 6.5000 | 13.1064 | 13.6398 | 0.5160 | 0.5370 | 0.258 | 0.079 | 787.239 | 803.609 | 529.000 | 540.000 |

| 2/0 | 19×70/30 | 139.7000 | 5.5000 | 11.6586 | 12.1412 | 0.4590 | 0.4780 | 0.338 | 0.103 | 625.029 | 641.399 | 420.000 | 431.000 |

| 1/0 | 19×55/30 | 127.0000 | 5.0000 | 10.3378 | 10.7696 | 0.4070 | 0.4240 | 0.398 | 0.121 | 494.070 | 504.488 | 332.000 | 339.000 |

| 1 | 19×43/30 | 114.3000 | 4.5000 | 9.1440 | 9.5250 | 0.3600 | 0.3750 | 0.499 | 0.152 | 386.923 | 394.363 | 260.000 | 265.000 |

| 2 | 19×35/30 | 101.6000 | 4.0000 | 8.2550 | 8.5852 | 0.3250 | 0.3380 | 0.635 | 0.194 | 314.003 | 321.443 | 211.000 | 216.000 |

| 4 | 19×7/25 | 76.2000 | 3.0000 | 6.3500 | 6.6802 | 0.2500 | 0.2630 | 0.977 | 0.298 | 193.461 | 197.926 | 130.000 | 133.000 |

| 6 | 19×7/27 | 63.5000 | 2.5000 | 5.0292 | 5.2832 | 0.1980 | 0.2080 | 1.557 | 0.475 | 121.732 | 124.262 | 81.800 | 83.500 |

| 8 | 19×7/29 | 50.8000 | 2.0000 | 4.0132 | 4.2164 | 0.1580 | 0.1660 | 2.445 | 0.745 | 77.087 | 78.426 | 51.800 | 52.700 |

| 10 | 37/26 | 38.1000 | 1.5000 | 2.6924 | 2.8448 | 0.1060 | 0.1120 | 4.213 | 1.284 | 44.198 | 44.794 | 29.700 | 30.100 |

| 12 | 37/28 | 31.7500 | 1.2500 | 2.1260 | 2.2581 | 0.0837 | 0.0889 | 6.757 | 2.060 | 27.829 | 28.275 | 18.700 | 19.000 |

| 19/25 | 25.4000 | 1.0000 | 2.2022 | 2.2987 | 0.0867 | 0.0905 | 6.197 | 1.889 | 28.573 | 29.168 | 19.200 | 19.600 | |

| 14 | 19/27 | 22.2250 | 0.8750 | 1.7475 | 1.8237 | 0.0688 | 0.0718 | 9.842 | 3.000 | 19.495 | 18.304 | 13.100 | 12.300 |

| 16 | 19/29 | 19.0500 | 0.7500 | 1.3945 | 1.4478 | 0.0549 | 0.0570 | 15.455 | 4.711 | 11.370 | 11.563 | 7.640 | 7.770 |

| 18 | 19/30 | 15.7480 | 0.6200 | 1.2319 | 1.2827 | 0.0485 | 0.0505 | 19.804 | 6.036 | 8.899 | 9.078 | 5.980 | 6.100 |

| 20 | 19/32 | 12.7000 | 0.5000 | 0.9830 | 1.0287 | 0.0387 | 0.0405 | 31.103 | 9.480 | 5.700 | 5.834 | 3.830 | 3.920 |

| 22 | 7/30 | 8.3820 | 0.3300 | 0.7468 | 0.7849 | 0.0294 | 0.0309 | 52.151 | 15.896 | 3.244 | 3.319 | 2.180 | 2.230 |

| 19/34 | 8.3820 | 0.3300 | 0.7722 | 0.8182 | 0.0304 | 0.0320 | 50.403 | 15.363 | 3.527 | 3.646 | 2.370 | 2.450 | |

| 24 | 7/32 | 8.3820 | 0.3300 | 0.5969 | 0.6274 | 0.0235 | 0.0247 | 81.634 | 24.882 | 2.083 | 2.128 | 1.400 | 1.430 |

| 19/36 | 8.3820 | 0.3300 | 0.6096 | 0.6477 | 0.0240 | 0.0255 | 80.877 | 24.651 | 2.232 | 2.322 | 1.500 | 1.560 | |

| 26 | 7/34 | 6.3500 | 0.2500 | 0.4674 | 0.4953 | 0.0184 | 0.0195 | 133.140 | 40.580 | 1.289 | 1.330 | 0.866 | 0.894 |

| 19/38 | 6.3500 | 0.2500 | 0.4851 | 0.5207 | 0.0191 | 0.0205 | 127.720 | 38.928 | 1.424 | 1.488 | 0.957 | 1.000 | |

| 28 | 7/36 | 5.0800 | 0.2000 | 0.3708 | 0.3912 | 0.0146 | 0.0154 | 211.540 | 64.478 | 0.789 | 0.845 | 0.530 | 0.568 |

| 19/40 | 5.0800 | 0.2000 | 0.3734 | 0.4064 | 0.0147 | 0.0160 | 215.560 | 65.702 | 0.856 | 0.911 | 0.575 | 0.612 | |

| 30 | 7/38 | 4.7498 | 0.1870 | 0.2946 | 0.3150 | 0.0116 | 0.0124 | 335.130 | 102.147 | 0.519 | 0.546 | 0.349 | 0.367 |

| 32 | 7/40 | 3.1750 | 0.1250 | 0.2286 | 0.2413 | 0.0090 | 0.0095 | 556.570 | 169.643 | 0.313 | 0.333 | 0.210 | 0.224 |